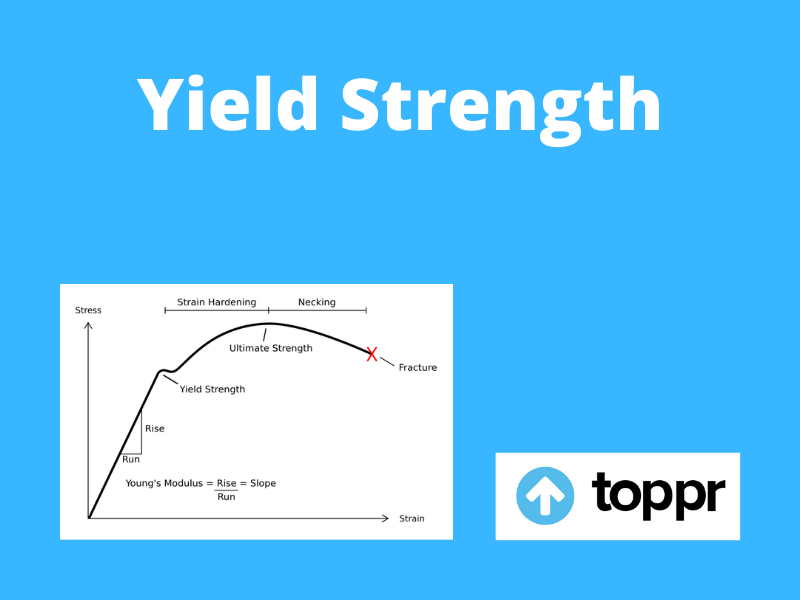

In other words, yield strength is the maximum stress that a material can withstand before it transitions from elastic deformation to plastic deformation. This means that once a material reaches its yield strength, it will no longer be able to return to its original shape when the stress is removed.

Yield strength is an important property for any material because it determines how much load it can bear before it fails. It is particularly important for materials that are used in structural applications, such as buildings, bridges, and aircraft.

One material that has a high yield strength is aluminum. Aluminum is a lightweight material that is commonly used in aerospace and automotive applications due to its high strength-to-weight ratio. Its yield strength can vary depending on the specific alloy and temper, but it typically ranges from 30 to 90 ksi (kilo-pounds per square inch).

One factor that affects the yield strength of aluminum is its purity. The purer the aluminum, the higher its yield strength will be. For example, 6061-T6 aluminum, which is a commonly-used alloy in aerospace and automotive applications, has a yield strength of 35 ksi.

Another factor that affects the yield strength of aluminum is the temperature at which it is tested. As the temperature increases, the yield strength of aluminum decreases. This is because at higher temperatures, the material becomes more prone to plastic deformation.

In conclusion, yield strength is an important property of any material that determines its ability to bear load without permanently deforming. Aluminum is a lightweight material that has a high yield strength, making it an ideal choice for structural applications in aerospace and automotive industries. Its yield strength can vary depending on the alloy and temper, but it typically ranges from 30 to 90 ksi.